Typically, conversions are more likely if someone already recognizes your brand. Conversion cost components and significance vary across industries, requiring tailored approaches. Lifetime value modeling is a crucial tool for startups looking to achieve long-term success.

- Similarly, the direct labor cost of a single bicycle will include $10 paid to the assembly worker, $2 ($8 per hour / 4 bicycles) paid to the worker that paints the bicycles.

- In summary, managing and reducing conversion costs requires a holistic approach, combining process optimization, strategic partnerships, employee engagement, and technological advancements.

- Calculating conversion cost is essential because manufacturers can determine the total product cost.

- So, the total conversion cost for Furniture Makers Inc. for the month is $14,300.

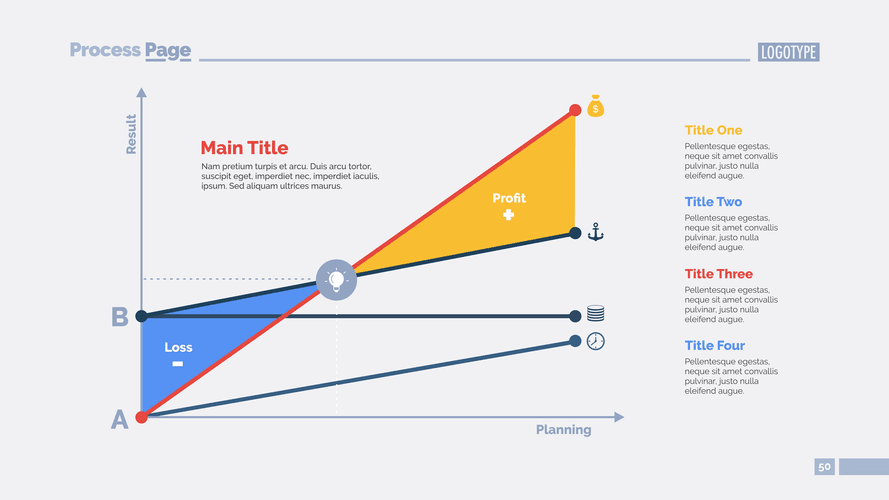

- The cogs is the cost of the goods that are sold during the accounting period, and it is deducted from the sales revenue to calculate the gross profit.

How to Calculate Stock Profit

Prime costs offer insights into material efficiency and workforce involvement. Conversion costs significantly impact product https://www.advantage-intec.co.jp/smart-tools-better-business-2/ pricing as they form a substantial portion of production expenses. Businesses must incorporate these costs into pricing models to maintain profitability and competitiveness.

How to Calculate Total Conversion Cost

Therefore, one difference between the two concepts is that manufacturing overhead is only included in conversion costs. The other difference is that the cost of direct materials is only included in prime costs. Thus, each cost concept provides a somewhat different view of the costs incurred to create products. Conversion cost is an important concept in accounting, particularly for manufacturers. It refers to Mental Health Billing the expenses incurred during the manufacturing process, which include direct labor and overhead costs. Manufacturing overhead includes all other production costs that cannot be directly attributed to labor or materials.

- Although the prime cost is computed and given at the start of the cost sheet, there is a fixed standard that requires the computation of conversion cost until and unless the manager demands it.

- In this section, we will delve into the topic of conversion cost efficiency and explore strategies to enhance the conversion process while minimizing costs.

- To illustrate, consider a manufacturing company that incurred $75,000 in direct labor costs for a specific production period.

- Overhead costs are factored into a company’s conversion costs because they are required for the transition of raw resources into final costs.

- Multiply this amount by their hourly wage rates to obtain total labor expenses.

Examples of Conversion Costs

As machinery and equipment become older and less efficient, this can affect the number of goods produced within a particular time. This can lead to higher conversion costs as it may require additional time or total conversion cost resources to produce the same amount of goods. Production processes vary depending on product complexity, batch size, and equipment. These variations can impact the time and resources required to produce a product, affecting the calculation of conversion costs. Automation can reduce the need for direct labor, significantly reducing labor costs.

- The make-or-buy decision is a multifaceted one that extends beyond simple cost analysis.

- Managers can view this information on the importance of identifying prime and conversion costs from Investopedia, a resource for managers.

- Prime costs and conversion costs are also different due to their presentations.

- Therefore, once the batch of sticks gets to the second process—the packaging department—it already has costs attached to it.

- Conversion costs are product costs, attached to goods produced, and remain with inventory until sold.

By understanding the nuances of conversion costs, businesses can enhance their financial performance and achieve sustainable growth. Remember, the key lies not only in calculating these costs but also in interpreting their implications for strategic management. Direct material costs encompass the expenses related to raw materials directly used in production. Calculating direct material cost involves multiplying the quantity of material used by its unit price. The cost of a product is all the expenditures borne on the production of the product.